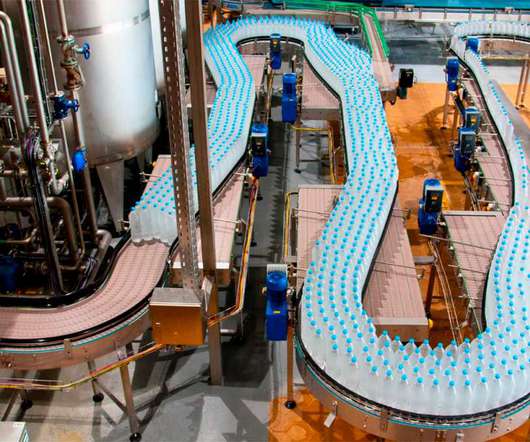

Data Analytics Solves Manufacturing Marketing Agency Challenges

Smart Data Collective

NOVEMBER 20, 2022

Data analytics is unquestionably one of the most disruptive technologies impacting the manufacturing sector. Manufacturers are projected to spend nearly $10 billion on analytics by the end of the year. Data analytics can solve many of the biggest challenges that manufacturers face.

Let's personalize your content