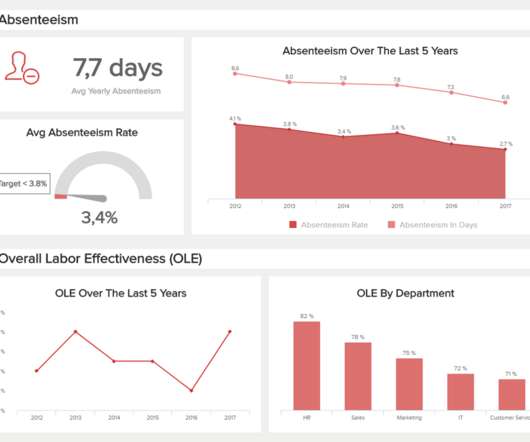

Top Productivity Metrics Examples & KPIs To Measure Performance And Outcomes

datapine

JULY 6, 2022

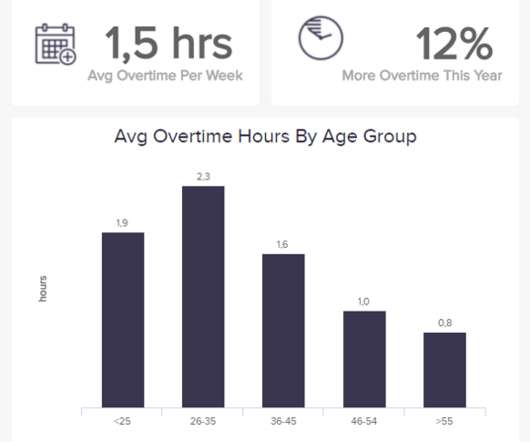

2) How To Measure Productivity? For years, businesses have experimented and narrowed down the most effective measurements for productivity. Use our 14-day free trial and start measuring your productivity today! In shorter words, productivity is the effectiveness of output; metrics are methods of measurement.

Let's personalize your content